ʻEkolu i loko o hoʻokahi mīkini welding laser

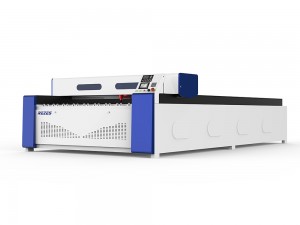

Hōʻike Huahana

ʻāpana ʻenehana

| Palapala noi | ʻOki ʻoki a me ka hoʻomaʻemaʻe ʻana i ka welding laser | Mea pili | Mea metala |

| Kahua Puna Laser | Raycus/MAX/BWT | CNC a ʻAʻole paha | ʻAe |

| Pulse Laulā | 50-30000Hz | Anawaena kiko kiko | 50μm |

| Mana Hoopuka | 1500W/2000W/3000W | Pūnaehana hoʻomalu | Ruida/Qilin |

| Ka lōʻihi o ka fiber | ≥10m | Loʻihi nalu | 1080 ±3nm |

| Palapala hōʻoia | CE, ISO9001 | Pūnaehana hoʻoluʻu | Hoʻoluʻu wai |

| Ke ano o ka hana | Hoʻomau | Hiʻona | Haʻahaʻa mālama |

| Hoike Hoao Mekini | Hāʻawi ʻia | Ka nānā 'ana i waho wikiō | Hāʻawi ʻia |

| Kahi i kumu | Jinan, Shandong | Ka manawa hoʻohiki | 3 makahiki |

Video Mīkini

ʻO ka hiʻohiʻona o ʻekolu i hoʻokahi mīkini welding laser

1. Kiʻekiʻe ikehu ikehu a me kiʻekiʻe kuʻihao ikaika

He kiʻekiʻe loa ka ikaika o ka ikehu laser beam o ka mīkini welding fiber laser mau, hiki ke hoʻoheheʻe koke i nā mea metala a hana i kahi weld paʻa. Hiki ke like a i ʻole ke kiʻekiʻe o ka ikaika wili ma mua o ka mea makua.

2. ʻO nā welds nani, ʻaʻohe pono o ka hoʻoponopono hope

ʻO nā welds i hana ʻia e ka welding laser he maʻalahi a ʻaʻahu, me ka ʻole o ka wili ʻana a i ʻole ka polishing, e hōʻemi nui ana i ke kumukūʻai o ka hana hope. He kūpono loa ia no nā ʻoihana me nā koi kiʻekiʻe no ka nānā ʻana i ka welding, e like me nā huahana stainless steel, ʻoihana hoʻonaninani metala, etc.

3. ʻO ka wikiwiki wiliwili wikiwiki a hoʻomaikaʻi i ka hana hana

Ke hoʻohālikelike ʻia me nā ʻano kuʻuna kuʻuna (e like me TIG / MIG welding), hiki ke hoʻonui ʻia ka wikiwiki o nā mīkini welding fiber laser mau e 2-10 mau manawa, hoʻomaikaʻi nui i ka hana hana, a kūpono i nā hiʻohiʻona hana nui.

4. wahi liʻiliʻi i hoʻopili ʻia i ka wela a me ka liʻiliʻi deformation

Ma muli o nā hiʻohiʻona kikoʻī o ka laser, ʻoi aku ka liʻiliʻi o ka hoʻokomo wela i ka wahi welding, e hōʻemi ana i ka deformation thermal o ka mea hana, ʻoi aku ka maikaʻi no ka welding i nā ʻāpana kikoʻī, e like me nā mea uila, nā mea lapaʻau, etc.

5. Hiki ke weld i nā ʻano mea metala, me ka nui o nā noi

Hoʻohana ʻia i ke kila kila, ke kila kalapona, ke alumini alumini, ke keleawe, ka nickel alloy, ka titanium alloy a me nā mea ʻē aʻe a me kā lākou mau mea hoʻohui, hoʻohana nui ʻia i ka hana kaʻa, ka hoʻoili ʻana i ka metala, aerospace, nā mea uila, nā mea lapaʻau a me nā ʻoihana ʻē aʻe.

6. ʻO ke kūlana kiʻekiʻe o ka automation, hiki ke hoʻohui ʻia me ka welding robot

Hiki ke hoʻohui pū ʻia ka mīkini welding fiber laser me nā robots a me nā ʻōnaehana CNC e hoʻokō ai i ka welding automated, hoʻomaikaʻi i ke kiʻekiʻe o ka hana akamai, hoʻemi i ka hana lima, a hoʻomaikaʻi i ka hana ʻana a me ka paʻa.

7. Hana maʻalahi a me ka uku mālama haʻahaʻa

Hoʻohana nā mea hana i kahi pānaʻi paʻi ʻenehana, nā ʻāpana hoʻololi, a me ka hana maʻalahi; he lōʻihi ke ola o ka laser fiber (maʻa mau a hiki i 100,000 mau hola) a me ke kumukūʻai haʻahaʻa haʻahaʻa, e hōʻemi nui ana i ke kumukūʻai o ka hoʻohana ʻana no nā ʻoihana.

8. Kākoʻo i nā ʻano lima lima a me nā ʻano maʻalahi

Hiki iā ʻoe ke koho i ke poʻo kuʻi lima lima e hoʻokō ai i ka wiliwili maʻalahi, i kūpono no nā mea hana nui a i ʻole; hiki ke hoʻohana pū ʻia me kahi papa hana automated a i ʻole robot e hoʻokō i nā pono o ka hana laina hui.

9. Pili kaiapuni a palekana, ʻaʻohe welding slag, ʻaʻohe uahi a me ka lepo

Ke hoʻohālikelike ʻia me ka kuʻuna kuʻuna, ʻaʻole hana ka welding laser i ka nui o ka uahi, nā ʻālohilohi, a me ka welding slag, ʻoi aku ka maikaʻi o ke kaiapuni a palekana, a hoʻokō i nā kūlana hana ʻōmaʻomaʻo ʻenehana hou.

Nā laʻana wiliwili

lawelawe

1.Customized lawelawe:

Hāʻawi mākou i nā mīkini welding fiber laser maʻamau, hana maʻamau a hana ʻia e like me nā pono o ka mea kūʻai. Inā ʻo ia ka welding content, ʻano mea a i ʻole ka wikiwiki o ka hoʻoili ʻana, hiki iā mākou ke hoʻoponopono a hoʻopaʻa pono iā ia e like me nā koi kikoʻī o ka mea kūʻai.

2. Kūkākūkā kūʻai mua a me ke kākoʻo ʻenehana:

Loaʻa iā mākou kahi hui loea o nā ʻenekinia hiki ke hāʻawi i nā mea kūʻai aku me nā ʻōlelo aʻoaʻo pre-sales ʻoihana a me ke kākoʻo ʻenehana. ʻO ke koho ʻana i nā mea hana, ka ʻōlelo aʻoaʻo noiʻi a i ʻole ke alakaʻi ʻenehana, hiki iā mākou ke hāʻawi i ke kōkua wikiwiki a maikaʻi.

3.Quick pane ma hope o ke kūʻai aku

Hāʻawi i ke kākoʻo ʻenehana wikiwiki ma hope o ke kūʻai aku e hoʻoponopono i nā pilikia like ʻole i loaʻa i nā mea kūʻai aku i ka wā e hoʻohana ai.

FAQ

Q: He aha nā mea e hiki ke hoʻopili ʻia e ka mīkini welding laser?

A: ʻO ka mīkini hoʻoheheʻe laser fiber mau ka mea kūpono no nā ʻano mea metala, e like me: ke kila kila, ke kila kalapona, ka alumini alumini, ke keleawe, ka nickel alloy, titanium alloy, galvanized sheet, etc.

No nā metala hoʻomanaʻo maikaʻi loa (e like me ke keleawe, aluminika), pono e koho i ka mana laser kūpono a me nā ʻāpana wili no ka loaʻa ʻana o nā hopena wili maikaʻi.

Q: He aha ka mānoanoa o ka welding mānoanoa o ka welding laser?

A: ʻO ka mānoanoa welding e pili ana i ka mana laser.

Nīnau: Pono anei ka welding laser i ke kinoea pale?

A: ʻAe, koi maʻamau ke kinoea pale (argon, nitrogen a i ʻole ke kinoea hui ʻia), a ʻo kāna mau hana he:

- Kāohi i ka oxidation i ka wā welding a hoʻomaikaʻi i ka maikaʻi weld

- E ho'ēmi i ka hanauna o ka weld porosity a hoʻonui i ka ikaika welding

- Hoʻoikaika i ka hoʻoheheʻe wai hoʻoheheʻe a hoʻomāmā i ka weld

Q: He aha ka ʻokoʻa ma waena o ka mīkini hoʻoheheʻe laser paʻa lima a me ka mīkini wiliwī laser maʻalahi?

A: Paʻa lima: He kūpono no ka hana maʻalahi, hiki ke weld i nā ʻano like ʻole a me nā mea hana nui, kūpono no ka hana liʻiliʻi a me ka liʻiliʻi.

Automation: He kūpono no ka hana nui, hana maʻamau, hiki ke hoʻohui i nā lima robotic a me nā keʻena hana wili e hoʻomaikaʻi ai i ka hana hana.

Nīnau: E hiki mai ana ka deformation i ka wā o ka welding laser?

A: Hoʻohālikelike ʻia me nā ʻano kuʻuna kuʻuna, ʻo ka welding laser he haʻahaʻa haʻahaʻa wela a me kahi wahi liʻiliʻi i hoʻopili ʻia i ka wela, a maʻamau ʻaʻole ia e hana i ka deformation maopopo. No nā mea ʻoi aku ka lahilahi, hiki ke hoʻoponopono ʻia nā ʻāpana e hōʻemi i ka hoʻokomo wela a hoʻemi hou i ka deformation.

Q: Pehea ka lōʻihi o ke ola lawelawe o nā mea hana?

A: Hiki i ke ola theoretical o ka fiber laser ke hiki i "100,000 mau hola", akā ke ola maoli nei i ka hoʻohana ʻana a me ka mālama ʻana. ʻO ka mālama ʻana i ka ʻoluʻolu maikaʻi a me ka hoʻomaʻemaʻe mau ʻana i nā mea optical hiki ke hoʻolōʻihi i ke ola o nā mea hana.

Nīnau: He aha nā pilikia e pono e hoʻolohe i ke kūʻai ʻana i ka mīkini welding laser?

A: - E hōʻoia i ka mea wili e pono ai a me ka mānoanoa, a koho i ka mana kūpono

- E noʻonoʻo inā pono ka welding automated e hoʻomaikaʻi i ka hana hana

- E koho i kahi mea hana hilinaʻi e hōʻoia i ka maikaʻi o ka lako a me ka lawelawe ma hope o ke kūʻai aku

- E hoʻomaopopo inā makemake ʻia nā ʻōnaehana hoʻoluʻu kūikawā