Mīkini Welding Laser Lima

Māhele maʻiʻo wehewehe pōkole

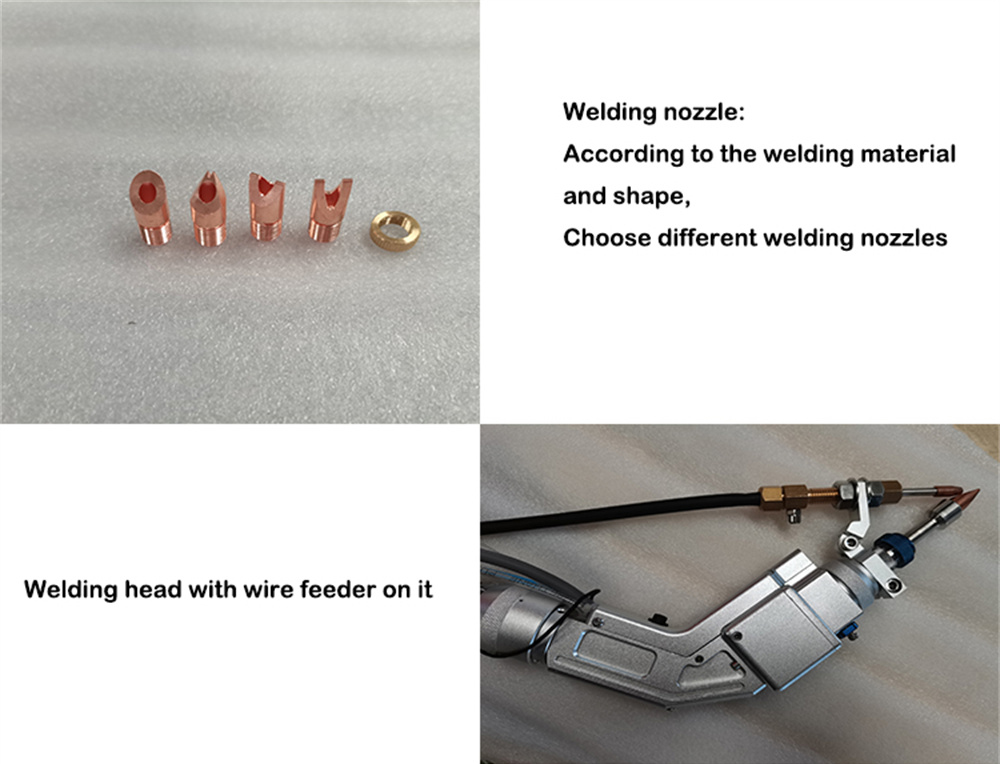

- Aia he 6 mau ʻano hoʻoheheʻe a me nā nozzles welding he nui e hoʻokō i nā pono wili like ʻole; loaʻa iā ia kahi hana ʻike palekana, e hoʻopuka ana i ka laser ma hope o ka hoʻopā ʻana i ka metala a hoʻopaʻa paʻa i ke kukui ke wehe ʻia.

- Hoʻolako ʻia ka mīkini me ka mea hānai uea maʻalahi, hiki ke hoʻoponopono maʻalahi i nā ʻāpana a hāʻawi i nā koho he nui no

nā mea kūʻai.

- Aia he 6 mau ʻano hoʻoheheʻe a me nā nozzles welding he nui e hoʻokō i nā pono wili like ʻole; loaʻa iā ia kahi hana ʻike palekana, e hoʻopuka ana i ka laser ma hope o ka hoʻopā ʻana i ka metala a hoʻopaʻa paʻa i ke kukui ke wehe ʻia.

- ʻO ka mahana pālua a me ka mana ʻelua, ke kaʻapuni wai kaʻapuni, hiki ke hōʻoluʻolu koke i ka lua pipeline kūloko o ke poʻo kuʻi, ʻoiai e hoʻoluʻu i ka laser.

Hōʻike Huahana

ʻāpana ʻenehana

| Kūlana | Hou | Nā mea kumu | Puna Laser |

| Hoʻohana | Weld Metal | Max. Mana Hoopuka | 2000W |

| Mea pili | Metala | Cnc A i ʻole | ʻAe |

| Ke ano hooluolu | Hooluu wai | Pūnaehana hoʻomalu | Ruida/Qilin |

| Pulse Laulā | 50-30000Hz | Mana Laser | 1000w/ 1500w/ 2000w |

| Kaumaha (Kg) | 300 Kg | Palapala hōʻoia | Ce, Iso9001 |

| Nā mea kumu | Puna Laser Fiber, Fiber, Handle Laser Weld Head | Na Kumu kuai nui | Kiekie-pololei |

| Hana | Kuʻihao ʻāpana ʻāpana metala | Ka lōʻihi o ka fiber | ≥10m |

| ʻOihana pili | Hokele, Halekuai lole, Halekuai Lako Hale | Nā mea kumu | Hoʻolako Laser |

| Ke ano o ka hana | Pulsed | Ma hope o ka lawelawe hōʻoia | Kākoʻo pūnaewele |

| Anawaena kiko kiko | 50μm | Loʻihi nalu | 1080 ±3nm |

| Nānā i waho wikiō | Hāʻawi ʻia | Kākoʻo ʻia ke ʻano kiʻi | Ai, Plt, Dxf, Dwg, Dxp |

| Wahi Hoʻomaka | Jinan, Shandong | Manawa Hoʻopaʻa | 3 Makahiki |

Nā Māhele Nui no ka Mīkini

Ka palena wili no ka mīkini wiliwili laser

Hoʻonohonoho

| Mana Laser | 1000w | 1500W | 2000W | ||||||

| Mea wiliwili | Kila kohu ʻole | ʻO ka hao hao | Aluminum | Kila kohu ʻole | ʻO ka hao hao | Aluminum | Kila kohu ʻole | ʻO ka hao hao | Aluminum |

| Mānoanoa welding (Mm) | 2 | 2 | 1 | 3 | 3 | 2 | 4 | 4 | 3 |

| Mānoanoa welding (ʻīniha) |

|

|

|

|

|

|

|

|

|

| Uea uwea hiki ke hoololi | ʻO ke anawaena uea welding 0.8-1.6mm | ||||||||

| Koi Weld Seam | Hoʻopili Wire Welding≤1Mm Swinging Weld ≤15% Of Plates Thickness≤0.3Mm | ||||||||

| Kaumaha Mīkini | 220Kg | 220Kg | 300Kg | ||||||

| Nui Mīkini (Mm) | 954X715X1080 | 954X715X1080 | 1155X715X1160 | ||||||

| Ka lōʻihi o ka laina pū welding | 10m(He 3 mika ka lōʻihi o ka pahu hānai uea o ka mea hānai uea) | ||||||||

| Welding Gun Weight | ʻAno Uʻi (Qi Lin):0.9Kg | ||||||||

| Mana Mikini | 7Kw | 9Kw | 12Kw | ||||||

| Kākoʻo ʻia ka ʻōlelo | Kūlana: Pākē, Pelekania, Kōlea, Vietnamese, Lūkini Hiki ke hoʻopilikino ʻia ʻo Iapana a me Sepania | ||||||||

| Voltage a me ka pinepine | Kūlana: 380V/50Hz Nā Voltage ʻē aʻe a ʻo ka pinepine ke koho | ||||||||

ʻoihana noi

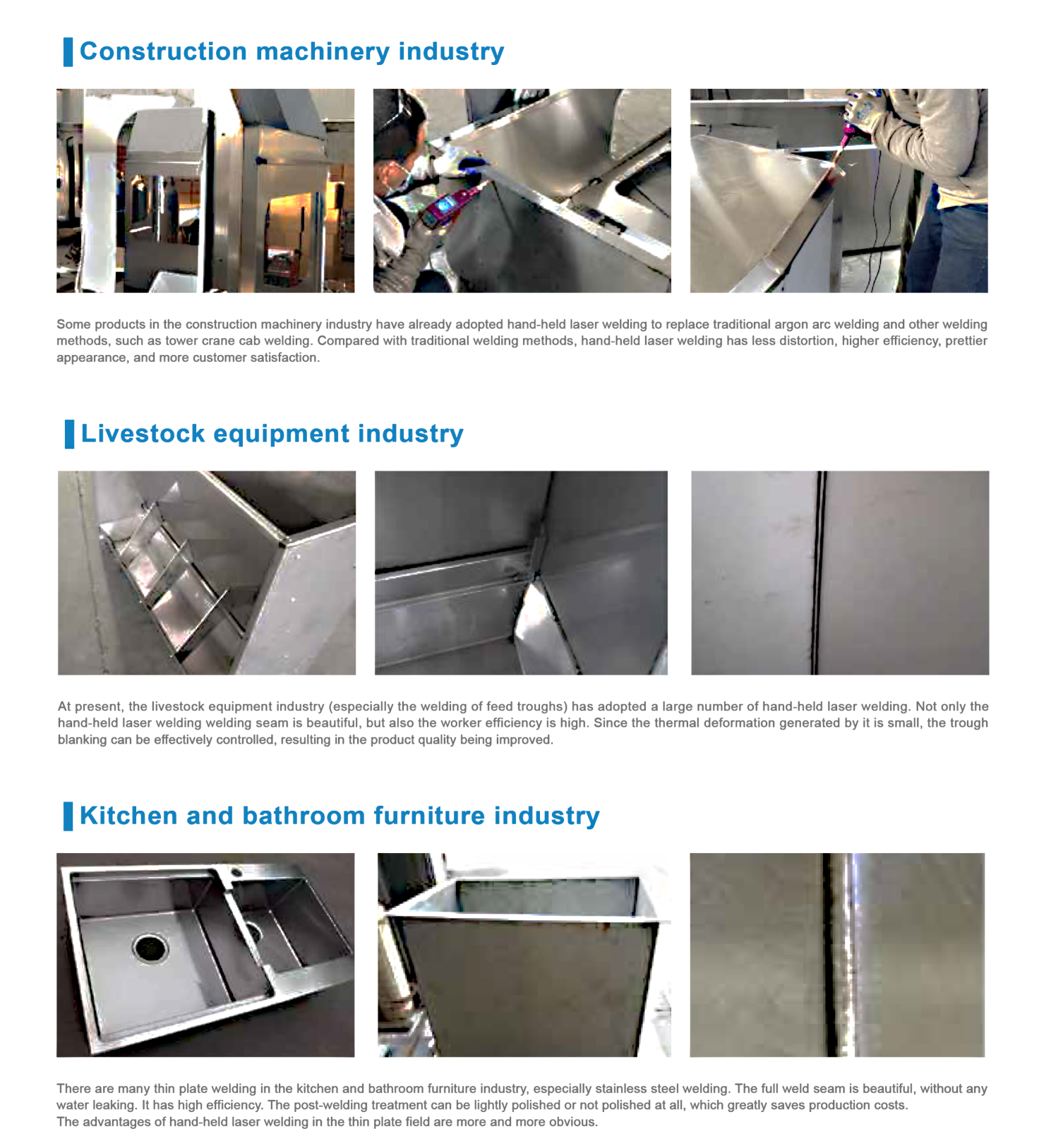

Hoʻohana nui ʻia nā mīkini hoʻoheheʻe laser i ka ʻoihana lumi ʻauʻau: ka hoʻoheheʻe ʻana i nā hui paipu wai, ka hoʻohaʻahaʻa ʻana i nā hono, nā tees, nā kīwaha, a me nā ua. ʻOihana aniani: ka hoʻopili pololei ʻana o ke kila kila, ka titanium alloy a me nā mea ʻē aʻe ma ke kūlana buckle, waho waho a me nā kūlana ʻē aʻe o nā aniani. ʻOihana paʻa: impeller, kettle, handle, etc., welding of complex stamping parts and casting parts. Hoʻohana nui ʻia nā mīkini hoʻoheheʻe laser i ka ʻoihana kaʻa: ʻenekini cylinder gaskets, hydraulic tappet seal welding, spark plug welding, filter welding, etc.

ʻO ka pōmaikaʻi o ka mīkini welding laser

1. ʻO ka laulā ākea ākea: Ua hoʻolako ʻia ke poʻo kuʻi lima lima me 5m-10m fiber optical original, e lanakila ana i ka palena o ka wahi hana a hiki ke hoʻohana ʻia no ka hoʻopili ʻana i waho a me ka wili lōʻihi;

2. Maikaʻi a maʻalahi hoʻi e hoʻohana: Ua hoʻolako ʻia ka welding laser paʻa lima me nā pulleys neʻe, kahi ʻoluʻolu e paʻa ai, a hiki ke hoʻoponopono ʻia i kēlā me kēia manawa, me ka ʻole o ka pono o nā kikowaena paʻa, manuahi a maʻalahi, a kūpono hoʻi no nā hiʻohiʻona ʻano hana.

3. ʻO nā ʻano hana hoʻoheheʻe like ʻole: hiki ke hoʻokō ʻia ke kuʻi ʻana ma kēlā me kēia kihi: wili kuʻi, kuʻekuʻe kuʻekuʻe, kuʻi kuʻekuʻe kuʻekuʻe, hoʻoheheʻe ʻia ʻana o ka fillet, ka hoʻoheheʻe ʻana i loko, ka hoʻoheheʻe ʻana o waho, etc. Hiki ke hoʻokō ʻia ka welding ma kēlā me kēia kihi. Eia kekahi, hiki iā ia ke hoʻopau i ka ʻokiʻoki, hiki ke hoʻololi ʻia ka ʻoki ʻana a me ka ʻoki ʻana, e hoʻololi wale i ka nozzle copper welding i ka nozzle keleawe ʻoki, kahi mea maʻalahi loa.

4. ʻO ka hopena hoʻoheheʻe maikaʻi: ʻo ka welding laser paʻa lima he welding fusion wela. Ke hoʻohālikelike ʻia me ka wili kuʻuna, ʻoi aku ka nui o ka ikehu o ka welding laser a hiki ke hoʻokō i ka hopena wili maikaʻi. ʻO nā pilikia kaohi, ka hohonu o ka wiliwili nui, ka hoʻoheheʻe ʻana, paʻa a hilinaʻi, a me ka ikaika weld e hiki ai a ʻoi aku paha ma mua o ka metala kumu ponoʻī, ʻaʻole hiki ke hōʻoia ʻia e nā mīkini welding maʻamau.

5. ʻAʻole pono e hoʻonaniʻia ke kuʻi welding: Ma hope o ka hoʻopili kuʻuna maʻamau, pono e hoʻonaniʻia ka helu kuʻiʻana e hōʻoia i ka maʻalahi aʻaʻole i ka'ōpala. Hōʻike ka welding laser paʻa lima i nā mea maikaʻi aʻe i ka hopena o ka hoʻoili ʻana: hoʻomau mau ʻia, ʻoluʻolu me ka ʻole o nā unahi iʻa, nani me ka ʻole o nā ʻulaʻula, a me nā kaʻina wili liʻiliʻi.

6. No consumables no ka welding: Ma ka hapanui o ka poʻe manaʻo, ka hana kuʻihao he "goggles ma ka lima hema a welding uwea ma ka akau lima". Eia nō naʻe, me ka mīkini hoʻoheheʻe laser paʻa lima, hiki ke maʻalahi ka hoʻopau ʻana, a hoʻemi ʻia ke kumukūʻai waiwai i ka hana a me ka hana.

7. Me ka nui o ka palekana palekana, ʻoi aku ka maikaʻi o ka welding tip ke hoʻopā ʻia ke kuapo i ka wā e hoʻopā ai i ka metala, a hoʻopaʻa ʻia ke kukui ma hope o ka wehe ʻia ʻana o ka mea hana, a loaʻa i ka pā hoʻololi ke ʻano wela kino. Palekana kiʻekiʻe, e hōʻoia ana i ka palekana o nā mea hana i ka wā o ka hana.

8. E mālama i ke kumukūʻai hana: Ke hoʻohālikelike ʻia me ka welding arc, hiki ke hoʻemi ʻia ke kumukūʻai hana ma kahi o 30%. He maʻalahi a maʻalahi ka hana a me ka wikiwiki e aʻo, a ʻaʻole kiʻekiʻe ka paepae ʻenehana o ka mea hoʻohana. Hiki ke hoʻohana ʻia nā limahana maʻamau ma hope o ka hoʻomaʻamaʻa pōkole, a hiki ke hoʻokō maʻalahi i nā hopena wiliwili kiʻekiʻe.